Power Rating, Density, & Surface Area

Power and Size – General Considerations and Metrics

A nuclear reactor can be operated at any desired power provided that the heat can be carried out of the core. In practice, the power is limited by industrial ability to make and deliver large components and the limiting temperatures of the fuel and materials in a given cooling architecture during operating and accident conditions. If cooling does not match the heat generation, temperatures increase, and the reactor will essentially turn off beyond certain temperatures. It will similarly shut down if it melts into a non-critical configuration – but the battle is lost with large remediation costs and leakage concerns even with a functional containment.

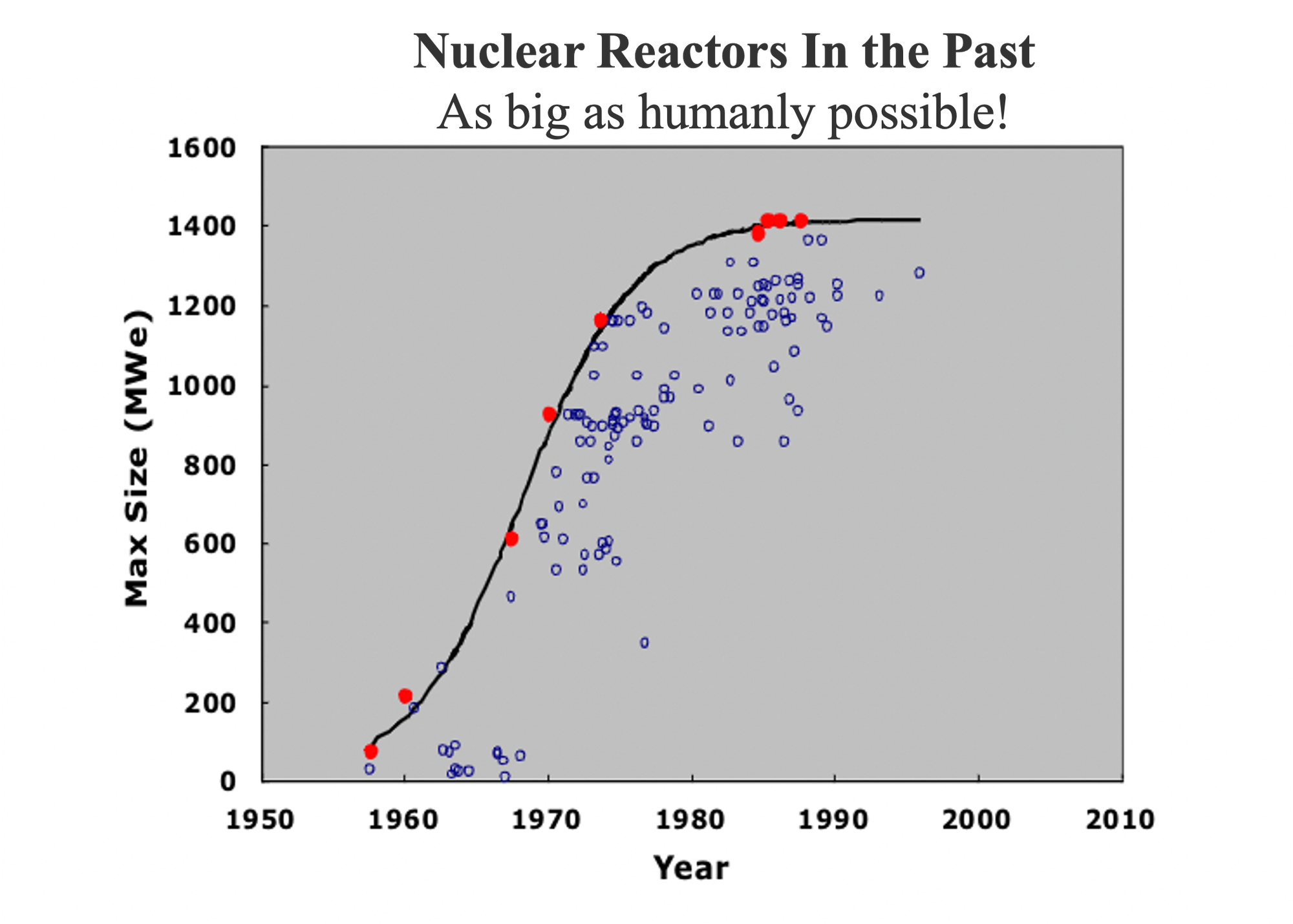

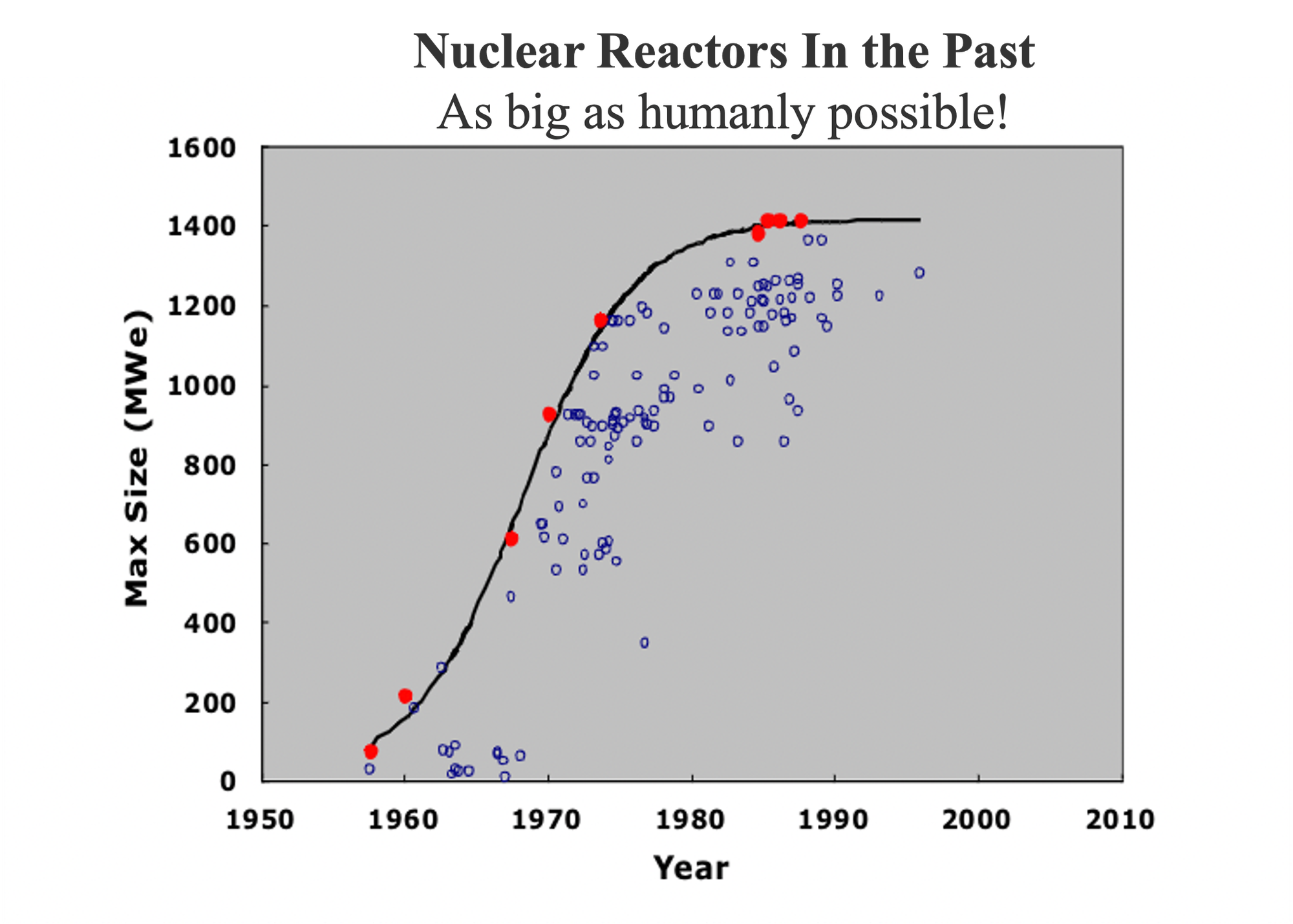

Traditionally, reactor power density has been determined by the maximum heat transfer that can be achieved with the given geometry and cooling fluid during operating conditions and favorably defined accident conditions. And power rating is determined by simply applying the power density to the entire core volume adjusting for power rating. This means designers have favored very high powers and high-power densities, irrespective of the size, even though the reactor will probably melt itself when conditions deviate from the carefully defined accident conditions. Below, we see how nuclear reactor power ratings have increased since inception, logistically approaching the size and complexity limits of practical turbomachinery and mega projects. Size and power are decoupled. Why seek the highest power? To reduce cost because it means the reactor materials are being maximally utilized per unit time.

The alternative is 100s of reactors producing the same total power as a few very large units. Nuclear utilities and operators often believe that reactor count is an important part of the operating cost and complexity. The count of micro reactors to achieve a power level is neither here nor there. It’s like trying to scare people by quoting the number of LiPo cells in a battery pack, or the number of transistors in a chip, or the number of car engines on the road. It is a very large number! For one, the reactors will probably all be coupled to one large BoP, achieving similar economies of scale on the power plant and turbine island side. Each reactor may require its own control system and could suffer from less efficient RPVs, HXs, and tubing – but the mere number of units may well have only a small effect on the total cost that is outweighed by economies of factory production. Similar production economies occur with large aircraft or automobiles which are produced at rates of ~2000 and ~100M per year, respectively.

Decay Heat Hazard

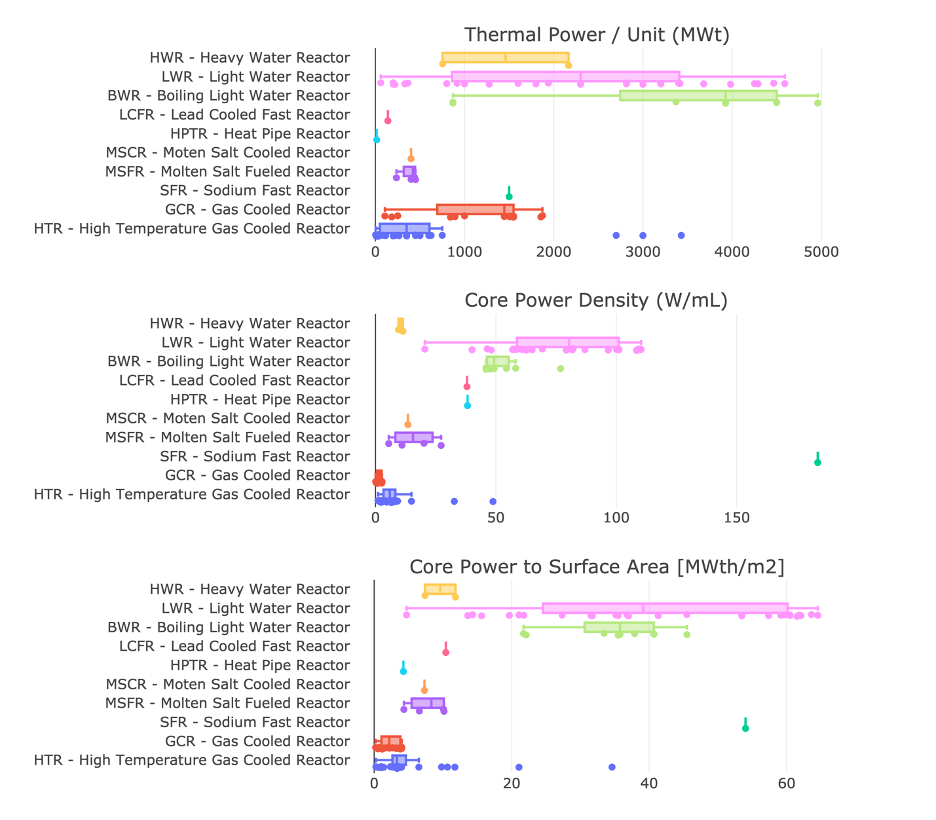

The principal way reactors fail is when operators are unable to sustain reactor cooling. When a reactor is turned off, it still produces roughly 7% of its full power as decay heat falling off with a power law of roughly -0.2 over the course of hours and weeks. But if cooling cannot be sustained continuously for any reason, this decay heat can be sufficient to cause fuel failures and fission product release. To make sure this does not happen, the reactor needs to run at sufficiently low power ratings, so that even if the operators cannot provide cooling, the reactor can cool itself or can manage to remain at safe temperatures. I first discuss power density, and surface area to power ratio (SAPR) metrics, and then consider a preliminary approach to define safety: limited power levels.

Power Density

Power rating and size determine the power density of the reactor. Higher power densities are more difficult to passively cool down. Higher power densities also lead to Xenon poisoning of the reactor core, which can prevent the reactor, depending on the concept from changing power quickly. PWRs in development have too high a power density to quickly change power to match demand because of Xenon poisoning. To overcome Xenon poisoning, they use excessive control rods or other neutron control systems. For some reactors, it takes hours and sometimes days to be restarted once it has been shut down.

HTGR tend to have sufficiently low power rating for their size to limit the worst-case accident temperatures from exceeding fuel failure temperatures. In extreme cases like MMR, low power density also means it has negligible xenon poisoning and can change power very quickly without inordinate amounts of reactivity insertion potential, though temperature gradients in the ceramic components must be carefully accounted for.

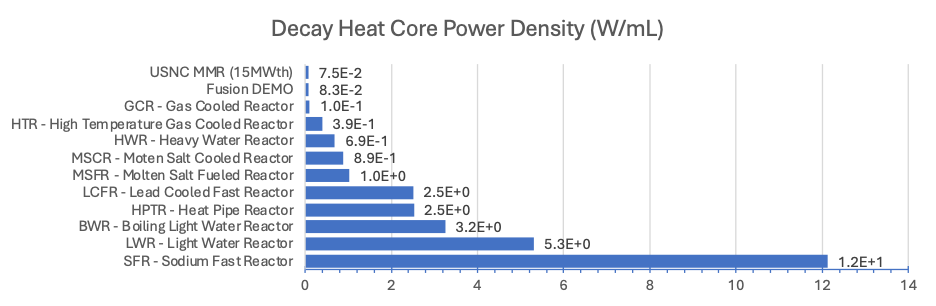

MMR in particular has a lower decay heat power density than fusion systems like SPARC, DEMO, or ITER and orders of magnitude lower than other prototypical advanced reactors as shown in the figure below. A lower decay heat is more manageable by passive cooling systems, allowing the reactor to dissipate heat more easily and without damaging the reactor. The other aspect to consider is the maximum temperatures that can be safely maintained in the reactor. HTGR cores can withstand much higher temperatures than a fusion’s reactors metals, molten salts, and magnets. UNSC's 15 MWth MMR has a lower initial decay heat power density of 0.075 W/cm3, less than DEMO’s 0.083 W/cm3 in the blanket and divertor.[2] The comparison would be less favorable for fusion 1 hour after shutdown when fusion’s decay heat is almost equal to fission’s decay heat.

Low enough power density also eliminates the need for water pool storage of used nuclear fuel. Current reactors produce used nuclear fuel that must be stored in large 12 m deep water pools for 2-5 years before being put into dry-storage casks. Reducing power density and decay heat can eliminate the wet storage and the fuel pool accident risk that was first experienced at Fukushima.

Surface Area to Power Ratio

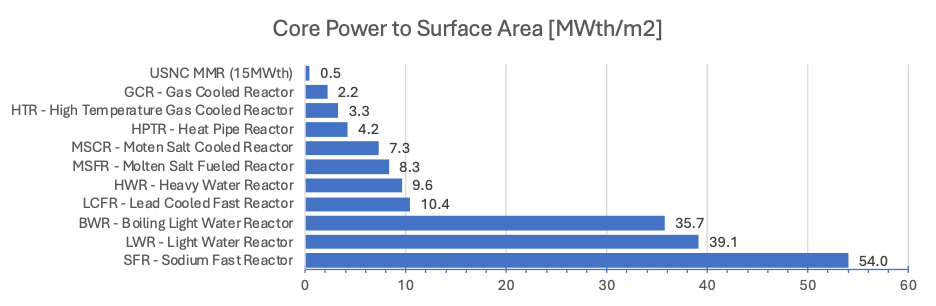

Another safety metric is the surface area to power ratio. SAPR is an indication of how much surface area the reactor has to dissipate excess heat during accidents. With sufficiently high SAPR, the reactor can dissipate all excess heat through conduction and radiation – totally passive and intrinsic heat transfer mechanisms that are basically guaranteed to work. Passive physical heat dissipation is based on physical laws and material properties and can occur through natural convection, conduction, or radiative heat transfer. The more intrinsic the heat dissipation mechanism, the stronger the argument for reduced safety systems. This makes radiative cooling and thermal conduction from an external surface superior to natural convection of liquid with internal flows. Natural convection can be mechanically obstructed and coolant pools can leak or become displaced, whereas conduction and radiation are intrinsic solid state physical mechanisms. In the context of IAEA’s passive system categories, [3] a Class A system requires no intelligent signals, no external power or force, has no moving parts, and has no working fluid. A Class B Safety system requires moving parts or fluids, but fundamentally relies on natural and passive mechanisms. An Active Safety system requires functional moving parts like pumps, may require operator action, and requires functional control systems.

If the power produced in the core is too high for the given surface area, the reactor temperatures can increase to the point where core components or structural components outside the core are damaged. Higher surface area to power ratio translates into a safer reactor as heat can be more easily dissipated by passive, solid state heat transfer. To summarize, there are a few knobs to improve resilience to decay heat: reduce power rating, increase surface area, or improve the thermal capabilities and temperature tolerance of the core materials. The last point can also include the use of a large heat sink in the reactor core, such as graphite blocks that can absorb heat and reduce temperature increases, as previously discussed.

[1] Li, “A Paradigm Shift Needed for Nuclear Reactors: From Economies of Unit Scale to Economies of Production Scale.”

[2] Someya et al., “Management Strategy for Radioactive Waste in the Fusion Demo Reactor.”

[3] IAEA, “Safety Related Terms for Advanced Nuclear Plants.”

[4] “IAEA Advanced Reactors Information System (ARIS) - Technical Data.”

[5] Sterbentz et al., “Special Purpose Nuclear Reactor (5 MW) for Reliable Power at Remote Sites Assessment Report.”

[6] “GE Hitachi Nuclear Energy BWRX-300 General Description.”